CASTER AND WHEEL GUIDES

CHOICE OF WHEELS

NUMBERING SYSTEM

CASTER NUMBERING SYSTEM

GUIDE TO SYMBOLS

WHEEL NUMBERING SYSTEM

WHEEL BEARINGS

CASTER SELECTION GUIDE

MOUNTING ARRANGEMENTS

TERMS AND CONDITIONS OF SALES

Choice of Wheels

This chart provides the basis for a general comparison of Bond Wheels and should

not be interpreted as a specific recommendation for any surface or operating condition.

You can return to web page that contains the specific wheel type by clicking on the type of wheel.

| |

Semi-Steel |

Solid Rubber Soft Tread |

Solid Rubber Hard Tread |

Bondcelon- Phenolic |

Vulc-On

G-1

Soft Tread |

Vulc-On

G-2

Hard Tread |

Vulc-On

G-3

Neoprene |

Bonduthane

Poylurethane on Steel/AL |

Anti-Static

Polyurethane |

TuffBond - UHMW |

Bondrelene- Molded Polyolefin |

| Floors |

|

|

|

|

|

|

|

|

|

|

|

Asphalt

|

|

X |

|

|

X |

|

X |

X |

X |

X |

|

Brick or tile |

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

Concrete |

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

Composite/

Vinyl Tile |

|

X |

|

|

X |

|

X |

X |

X |

X |

|

Ribbed Steel |

|

|

|

|

X |

|

X |

X |

X |

X |

|

Smooth Steel |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

Terrazzo |

|

X |

|

|

X |

|

X |

X |

X |

X |

|

Wood Block |

X

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

Hard wood |

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

| Operating Conditions |

|

|

|

|

|

|

|

|

|

|

|

Water |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

Oil, Grease |

X |

|

|

X |

|

|

|

X |

X |

X |

X |

Animal fats |

X |

|

|

X |

|

|

|

X |

X |

X |

X |

Industrial Chemicals |

X |

|

|

X |

|

|

|

X |

X |

X |

X |

Low Temperature

(-20 degree F) |

X |

|

|

X |

X |

X |

X |

X |

X |

X |

X |

High Temperature

(+160 degree F)

|

X |

|

|

X |

|

|

|

X |

X |

X |

X |

| Characteristics |

|

|

|

|

|

|

|

|

|

|

|

Floor Protection |

Low |

High |

Medium |

Medium |

High |

Medium |

High |

High |

High |

High |

Medium |

Ease of Rolling |

High |

Low |

High |

High |

Low |

High |

Low |

Medium |

Medium |

High |

High |

Quiet Operation |

No |

Yes |

No |

No |

Yes |

No |

Yes |

Yes |

Yes |

Yes |

No |

Resiliency |

Low |

High |

Medium |

Low |

High |

Medium |

High |

Medium |

Medium |

Medium |

Low |

Shock resistance |

Low |

High |

Medium |

High |

High |

Medium |

High |

Medium |

Medium |

Medium |

High |

Abrasion resistance

|

High |

Low |

Medium |

Medium |

Low |

Medium |

Low |

High |

High |

High |

Medium |

Relative Capacity |

High |

Low |

Medium |

High |

Low |

Medium |

Low |

High |

High |

High |

Medium |

Static

Dissipation |

No |

No |

No |

No |

No |

No |

No |

No |

Yes |

Yes* |

No |

*

Numbering Systems

Caster Numbering System

The Bond Numbering system for casters is an easily understood, easy-to-use, three part designation which includes wheel and bearing type, basic caster series, and wheel diameter. Optional features are added to the suffix. All Bond Swivel Casters are designated with an even number (except for the 3-A Series). Rigid casters are designated by odd numbers.

| Catalog number |

Bearings |

Wheels |

Caster Series |

Wheel Diameters |

Wheel width or Features |

Description |

| 3ST50-A-2 |

None |

3ST |

50-A |

2 |

|

Plain bearing, solid soft tread rubber wheel, 50-A series/swivel/plate, 2" diameter |

| 141-A-5-WS |

1 |

|

41-A |

5 |

WS |

Bearing, semi-steel, 41-A series/Rigid/Plate, 5" diameter, Wheel Grease Seals |

| T1874-A-12-4 |

T1 |

8 |

74-A |

12 |

4 |

Tapered Bearings, Bonduthane wheel, 74-A series/Swivel/Plate, 12" diameter, 4" wheel width |

| 152-J-3-SP |

1 |

|

52-J |

3 |

SP |

Bearing, Semi-Steel, 52-J/swivel/stem, 3" diameter wheel, Special Product |

Guide to Symbols

Bearings |

Symbol |

Wheel Type |

Symbol Caster |

Symbol Wheel |

Caster Series |

Optional features and Wheel Diameters

|

| Straight Roller |

1 |

Semi-Steel |

None |

casting no. |

|

Optional Features |

Symbol |

| Tapered |

T |

V-Grooved |

VG |

|

See |

Thread Guards |

TH |

| Ball Bearings |

BB or SP |

Single Flanged |

SF |

|

Caster |

Swivel Lock |

|

| Press Fit Bushings |

|

Solid Rubber Soft |

3ST |

SRWS |

Index |

2 Position |

SL2 |

Standard |

None |

Solid Rubber Hard |

3HT |

SRWH |

|

4 Position |

SL4 |

Custom |

SP |

Bondcelon/Phenolic |

4 |

BC |

|

Brakes |

|

| Plain Bearing |

None |

Vulc-on G-1 Soft |

5 |

|

|

Swivel & Wheel Brake |

SWB |

| |

|

Vulc-on G-2 Hard |

6 |

|

|

Top Lock CAM Brake |

TLB |

| |

|

Vulc-on G-3 Neoprene |

7 |

|

|

Total Lock Brake |

TTB |

| |

|

Bonduthane / Polyurthane |

|

|

|

Wheel brake CAM Style |

SB |

| |

|

Polyurethane tread on Steel Centers |

8 |

U |

|

Grease Seals |

|

| |

|

Polyurethane tread on AL Centers |

8 |

AU |

|

Swivel raceway(s) seal |

GS |

| |

|

Solid Polyurethane |

8 |

PU |

|

Wheel/axle seal |

WS |

| |

|

Bondrelene/Polyolefin |

9 |

P |

|

Special Options |

SP |

| |

|

TuffBond /UHMW |

9 |

UHMW |

|

Wheel Diameter - Numbers represent the actual diameter in inches. Half inch increments are noted by the number 5 (2-1/2" = 25) |

Wheel Numbering System

| Catalog number |

Bearings |

Wheel Diameter |

Wheel Number or Symbol |

Wheel Face |

Bearing ID

or Bore Diameter

(in 16th's of an inch) |

Description |

1-25-VG3072-15-8 |

1 |

25 = 2.5" |

VG3072 |

15=1.5" |

8 = 1/2" ID bearing |

2.5"diameter X 1.5" face width v-grooved steel wheel with 1/2" ID Straight Roller Bearing |

T-12-3304-4-20 |

T |

12 |

3304 |

4 |

20 = 1-1/4" ID bearing |

12" diameter X 4" face width steel wheel with 1-1/4" tapered bearing |

8-2732-2-16 |

none |

8 |

2732 |

2 |

16 = 1" plain bore |

8" diameter X 2" face steel wheel with 1" plain bore |

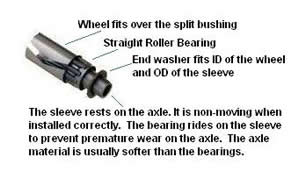

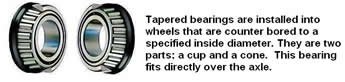

WHEEL BEARINGS |

|

Straight Roller Bearing Assembly includes a split outer raceway, steel rollers held parallel to the axle by a steel retainer, and end washers. A steel sleeve that fits over the axle is recommended. |

|

Tapered Roller Bearings includes two bearings per wheel that ride directly on the axle. |

|

Ball Bearings includes two bearings per wheel. These are available with and without seals, flanged or with an inner raceway often called a top hat or sleeve. |

|

|

Press fit bushings for special applications such as Steel or bronze for heated applications, Delrin or nylon for wash down, or sintered metal with oil imprgnated for industrial applications. |

Caster Selection Guide

There is no single formula that is valid in every situation for the selection of a caster. There are; however, standards established by the members of the Caster and Wheel Institute, a division of the Materials Institute of America which greatly facilitate caster selection according to class of service, component function and wheel application. Bond adheres to these standards in the classification and presentation of its casters.

Bond casters are used universally throughout industry and their applications are broad as they are varied. Standard Bond casters are available with wheel diameters ranging from 2" to 12" and in capacities from 75 to 6,000 lbs. per caster. Custom products can be produced outside of this product range for instance; custom wheel's can be as small as 1-5/8" or as large as 20". Custom casters can range from 30 to 20,000 lbs capacity.

Caster construction and wheel treads take into consideration intermittent as well as continuous service over the widest variety of floor surfaces. Bond capacity ratings were arrived at through a continuous testing and evaluation program and may be relied upon as a valid comparison of the relative performance values of the casters offered. However, due to the multiple variables in caster application, the users experience and knowledge of his operating environment must be an important consideration in the selection of a caster to meet an individual requirement. |

Primary Features for Caster Selection

Mounting height is the distance from the top of the plate to the floor. If a stem caster is used it is the distance from the insertion point of the mounting leg to the floor. This is used to design carts and to purchase truck locks.

Swivel radius is a measurement used to insure the caster remains under the cart or does not interfere with legs or skirts.

Offset is a measurement used to define the angle of the fork. A longer offset is easier to swivel.

Wheel Diameter and wheel width define the wheel size used to chose the correct

caster dimensions.

|

| CONSIDERATIONS IN CASTER SELECTION |

|

LOAD - the load is comprised of the net weight of the material or equipment to be transported plus the weight of the vehicle, frame or other apparatus used in the conveyance. This total weight is then divided by the number of casters necessary for the mobility and maneuverability desired. The result is the caster capacity necessary to safely move the load. A size larger caster may be advised if the floor is rough or uneven or contains other impact causing obstacles.

TYPE OF SERVICE – Intermittent? Continuous? Manual or mechanically powered? Each requires separate consideration. Occasionally moved loads, short travel distances or for dollies used to move material in storage or warehouse operations, a single ball race caster with or without anti-friction wheel bearings could be the wise and least expensive choice. For continuous service, either manually or mechanically powered, a heavier duty double ball race caster with anti-friction wheel bearings is indicated. Mechanically powered trailer-type operations require special heavy duty construction with large swivel bearings to withstand the impact and shock encountered. Bond casters and wheels are listed by the weight classification. You will find this |

useful as an excellent aid for preliminary determination. Complete details and specifications on each series should be referred to in making your final determination.

WHEELS – TREAD, DIAMETER, FACE – Wheel selection must be made with great care for it can not only determine the life of the caster but the life of the floor over which it travels. Floors are expensive and therefore, must receive primary considerations – click here – to return to the wheel selection guide. Other tips on wheels. Large wheels roll easier than small wheels. Hard treads roll easier than soft treads. Resilient treads roll over rough surfaces more easily than hard treads. Larger wheels mean larger bearings …longer life and easier rolling.

OTHER CONSIDERATIONS – The environment in which a caster will be used must also be considered. Is noise a factor? Dirt, chips, threads or other detrimental substances? Grease, oil, water, steam or chemicals? Temperature extremes? Through various options, lubricants and tread selections, Bond can help you find the caster / wheel combination right for your application. |

| |

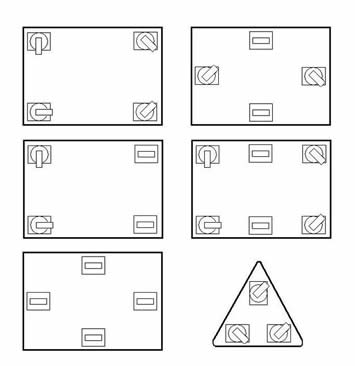

CASTER MOUNTING ARRANGEMENTS |

|

FOUR SWIVEL - Maneuverable in any direction. Ideal for confined areas or where equipment must be moved sideways. Difficult to steer in a straight line travel.

TWO SWIVEL TWO RIGID - Easily steered or pushed for straight line travel/ Trails well. Used on a variety of portable equipment.

FOUR RIGID- Diamond pattern, tilt type (usually the center wheels are larger diameter than the ends wheels). Good for light loads, straight travel. Economical. |

|

TWO SWIVEL TWO RIGID - Diamond pattern, tilt type (usually the center wheels are larger diameter than the ends wheels). Highly maneuverable in tight areas. Turns in own length.

FOUR SWIVEL TWO RIGID - tilt of level type. Highly maneuverable; turns in own length. For heavy loads of long trucks.

THREE SWIVEL - Use where easy motion in any direction is desirable. Barrel dollies, wharehouse dollies, light machinery. |

TERMS AND CONDITIONS

Prices: All quotations are offered at FOB Manheim, PA 17545 unless otherwise agreed upon and are subject to change without notice.

Terms:

Credit Cards: Bond accepts all credit cards draw on a United States Bank except The Discover Card.

Net 30 day terms: Credit can be established with an approved credit application. The credit application requires the company name, address, phone, fax and three or more trade references with name, address, and phone and fax number.

COD: Bond will accept business with a UPS COD payment. The customer is responsible for all fees associated with the COD payment method.

Orders: Orders regularly entered can not be countermanded, except with our consent and upon terms that will indemnify us against loss.

Agreements: All agreements and contracts are contingent upon strikes, fires, accidents, or other causes beyond our control.

Delivery: If shipping instructions are not given it is understood that we are to decide how the order is to be packed and shipped. We are not responsible for goods after delivery is made to the Transport Company and we have obtained a receipt from them “in good order”. If there are shortages, or evidence of damage they should be noted on the shipping documents by the Transportation Agent before receipt is signed. It desired, we will cooperate with customers to obtain adjustments from Transportation Company.

Warranties: We warrant all articles sold and made by us to be free from defects in materials and workmanship; our obligation under this warranty to be limited to repairing or replacement at our factory any new equipment within six months after shipment when returned to us by our customer, transportation prepaid and which our examination should disclose to have been defective. This warranty being expressed in lieu of all other warranties expressed or implied and of all obligations or liabilities on our part, contractual or otherwise, either to the original purchase or to any other person. We shall be liable on this warranty only if you as a purchaser make prompt inspection of the goods delivered and give us five days of receipt of the material notice of any such defects. We will not assume liability for charges of labor, consequential expense or damages incurred.

Returned Material: Material returned without our permission will not be accepted. We can not accept the return of material that ahs been altered or damaged until the customer has first notified us in writing and we have given written consent for the return. There will be a charge made on all returned material, this charge depending on the amount of expense involved in handling and putting the material in saleable condition.

Dimensions: The dimensions given in this written material are as nearly correct as is possible to compile them. We do not hold ourselves responsible for claims for damages on account of typographical errors and reserve the right to change our patterns, dimensions, designs and construction at any time without notice.

Claims: Claims for corrections or deductions must be filed within five days after receipt of goods, reference should always be made to date and number invoice.

Correspondence: In order to receive immediate attention and avoid delays, all correspondence should be addressed to the Company and not to individuals.

Trademarks: Wherever the name “BOND” appears in script form as illustrated on the title block of these pages, it is understood that the name is registered in the United States Patent office, whether indicated under a cut or not, and that this registration applies to all items of our manufacture in Casters, Wheels, Truck Locks, and Material Handling Equipment.

Contact us with your needs.

TELEPHONE: 800-233-2663 or EMAIL: sales@bondcaster.com

|